Home > Company News > Future Development Trends of Metal Working Fluids

Company News

Future Development Trends of Metal Working Fluids

Cutting fluids are widely used in modern manufacturing, and metal cutting in modern manufacturing will develop towards high speed, strength, and precision. Advanced manufacturing technologies such as CNC machine tools, machining centers, and flexible manufacturing systems have gradually been promoted and applied. Advanced manufacturing technology and cutting of difficult to machine materials are inseparable from cooling and lubrication technology, so cutting fluids are becoming increasingly important.

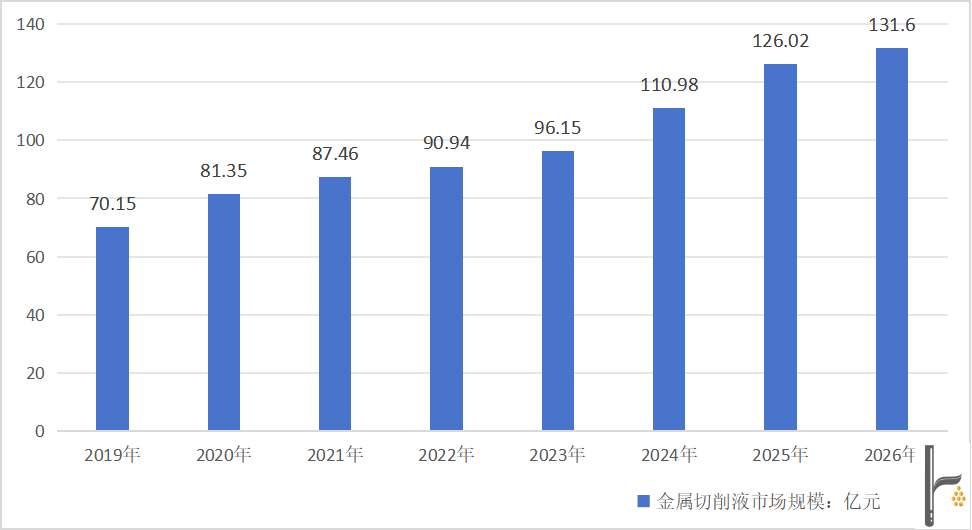

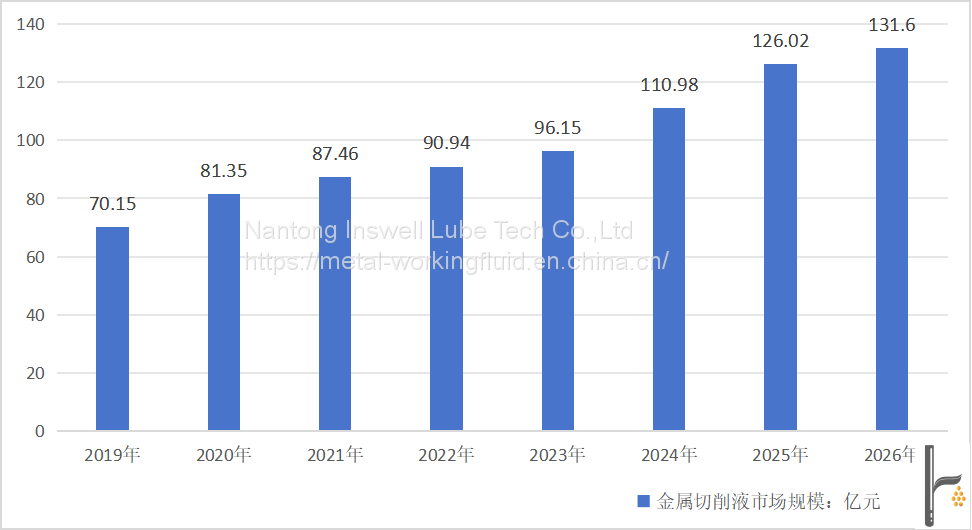

It is expected that the market size of China's cutting fluid industry will exceed 13 billion yuan by 2026.

1、 From the perspective of product market development

With the increasing demand for intelligent manufacturing in China, the demand for cutting fluids has naturally increased. Cutting fluid, as an auxiliary agent for metal processing, plays a role in improving equipment life, precision, and processing speed in cutting, and has huge potential for future development.

2、 From the perspective of product type and technology

Cutting fluids are divided into emulsified cutting fluids, semi synthetic cutting fluids, synthetic cutting fluids, and oil cutting fluids.

In recent years, although many monomer raw materials have been continuously developed, most of them are only simple modifications to the molecular structure of traditional raw materials or better purification of products, and there are few revolutionary improvements to the molecular structure of traditional raw materials.

Enswei's fully synthetic cutting fluid can meet the high requirements of modern machine tools in terms of lubrication and extreme pressure functions, reducing the situation of traditional cutting fluid corruption and difficult to control.

3、 From the perspective of cutting fluid cost

On June 30th, the Ministry of Finance and the State Administration of Taxation issued a tax expansion policy for refined oil products, which directly increased the cost of producing metalworking fluids.

Making fully synthetic or high water content microemulsions with low cost; High cost-effectiveness; Good overall performance; Long service life, etc; This solves the problem caused by the re expansion of the consumption tax on finished oil products. The lower the oil content in the product, the less it will be affected by the increase in consumption tax revenue, allowing metalworking fluids to eliminate their dependence on oil.

In short, in the future, enterprises in the cutting fluid industry will continue to expand production scale, improve product quality, and further intensify market competition within the same industry. The cutting fluid market will be a vibrant market, especially in developing countries.

-

Sinpec /Great Wall L-QD350 Heat Transfre Fluids

-

refrigeration oil 400ML*12

-

Fully synthetic POE refrigeration oil 200L

-

Fully synthetic POE refrigeration oil 200L

-

SYN-2830HT Polyol Ester POE Synthetic Ester-based Oil for Engine Oils

-

SYN-2820HT Polyol Ester POE Synthetic Ester-based Oil for Engine Oils

-

Biodegradable Synthetic Ester oil Polyol Complex Ester

-

SYN-40HT synthetic ester-based oil Ester-based PAO Polyester

-

SYN-35HT synthetic ester-based oil Ester-based PAO Polyester

-

SYN-25HT synthetic ester-based oil Ester-based PAO Polyester

-

synthetic ester-based oil Ester-based PAO Polyester

-

POE Ester Oil for Transformer Oils

-

SYN-1830HT synthetic ester-based oil Ester Oil Diester

-

synthetic ester-based oil Ester Oil Diester

-

synthetic ester-based oil Polyol Ester POE320 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE170 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE150 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE120 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE100 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE68 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE46 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE32 for Refrigeration Oil

-

synthetic ester-based oil Polyol Ester POE22 for Refrigeration Oil

-

TMPTO68 Trimethylolpropane Trioleate for Difficult-flammble Hydraulic Fluid(HFDU)